Press

Order Fulfillment for Modern Retailers: Process, Strategy & Services

Mar 18, 2023

Learn about order fulfillment solutions and technology to support your operation.

If you’ve ever made a purchase online, then you know how nice it is to receive a package at your door shortly after you order it. But most people don’t think about the process behind order fulfillment services that make fast shipping possible. A lot goes on behind the scenes. The ability to ship an order quickly, accurately and affordably is a well-designed, streamlined process with several steps, each just as important as the next. Just one misstep can result in an unhappy customer and loss of future sales. This entire process is known as order fulfillment. With the rise of omnichannel retail, inventory management has become more complex while customer’s expectations are higher.

“What’s at stake? Ecommerce sales are projected to surpass $735 billion by 2020”

— Statista

In this article, we’ll walk you through order fulfillment, beginning with what it is and how it works, and explain the different types of fulfillment models and strategies. We’ll also cover the issues that retail brands experience with order fulfillment as they grow, and when to know it’s time to outsource order fulfillment services (3PL). Today there are several technology solutions available in the market to support and scale fulfillment for growing retail brands, and it’s important to choose the provider that best suits your company’s needs. This article will walk you through:

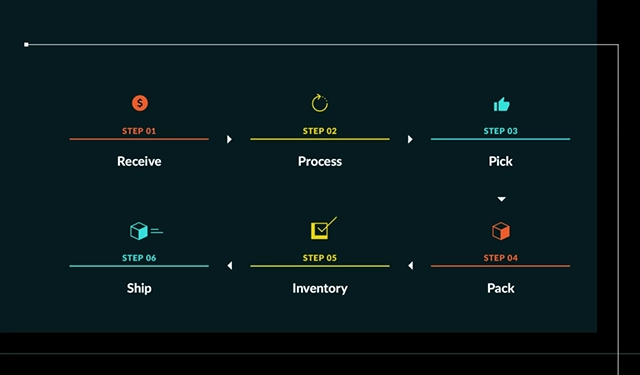

Six Steps of the Order Fulfillment Process

Fulfillment Strategies, Pros & Cons

Issues Companies Experience With Fulfillment as They Grow

When to Switch from In-House Fulfillment to a Service Provider

How MasonHub’s Technology Supports and Scales

What is Order Fulfillment?

Order fulfillment is the process of receiving, packing, and shipping online orders to end consumers at home.

You could say that order fulfillment is the number one thing that impacts the customer experience, because if a customer doesn’t receive their order in a timely and accurate manner, they aren’t likely to buy from that company again.

It is a customer’s order that sets the retail supply chain in motion. We’ll detail the steps that need to happen in the next section, but in short, order fulfillment involves inventory going to a fulfillment center, which receives and stores it. Once the fulfillment center receives and processes an online order, it picks, packs, and ships the item to the end customer. Order processing refers to the workflow associated with picking, packing and delivery of the items to a shipping carrier and is a key element of order fulfillment.

There are several types of ecommerce fulfillment models: in-house or self-fulfillment, drop shipping, and outsourcing fulfillment to a third-party logistics (3PL) company. An ecommerce company could use one or a combination of these. We’ll explore each model in-depth later on.

The Six Steps of Order Fulfillment

1. Receiving

Receiving refers to accepting incoming inventory from the manufacturer, supplier, or ecommerce brand. Whether you outsource your order fulfillment or do it in-house, key tasks in the receiving process include:

- add each new SKU to an inventory or warehouse management software

- count and inspect items to ensure accuracy

- check for any possible damages

- apply SKU or barcode labels

- record the number of each SKUS in the inventory or warehouse management system

- kit any items that go into bundled SKUS

2. Inventory Storage

Proper inventory storage makes for quick and easy picking. This is crucial for order fulfillment speed and accuracy. Moreover, it provides full visibility into what is available to ship and where to find it. Often, inventory organization involves putting SKUs in separate bins to enable fast and accurate picking and packing.

3. Picking

The first physical step for preparing an order for proper shipping is picking, where the item is located and retrieved from the shelf and bin. The person picking the order will also scan the barcode to verify the picked item matches the order.

4. Packing

Packing involves wrapping all the items to protect them in transit and using the right materials depending on the type(s) or items ordered. Materials can include boxes, bubble mailers, poly bags, bubble wrap, air fill and packing tape. During this step, workers add packing slips and any inserts before sealing the package and moving it to the shipping station.

5. Shipping

It is the responsibility of the employee at the shipping station to weigh the package and determine the best method for the order. There are several ways to ship a package, but most customers are looking for the fastest and most affordable way. Different shipping carriers provide different options, ideally compared to find the best rates or service level, in a function known as rate shopping. Once an order ships, the tracking information goes to the customer to provide insight on its delivery status.

6. Returns Processing

If an ecommerce company offers returns, these are also part of the order fulfillment process. Returns must also be processed quickly and efficiently to maintain a good customer

Fulfillment Strategies, Pros & Cons

There are four primary ways that businesses can handle order fulfillment.

1. In-house Fulfillment

In-house fulfillment, or self-fulfillment, refers to when businesses manage their own warehouse and shipping operations, typically with their own facility, equipment and staff. This method is best for established businesses or businesses that want total control over their end-to-end operations.

Pros

- Hands-on: Fulfilling orders yourself allows you to learn all the ins and outs of ecommerce operations.

- Cost-effective: For new business, this is an extremely low-cost way of fulfilling orders.

- Complete control: You have the ability to personally oversee all aspects of your business.

Cons

- Potential to outgrow your space suddenly.

- Time-consuming: Time spent filling orders means less time for marketing, managing, sourcing and growing your business.

- Difficult to downsize: Once you commit to warehouse space, it may be hard to downsize during less busy times or when sales slow down.

- Large up-front costs

2. Outsourced Fulfillment

Companies can outsource order fulfillment by using fulfillment service providers or 3PL (third-party logistics) companies. Fulfillment service companies specialize in inventory management, order processing, order management, and shipping. This is a good option for businesses that want to save time by not handling these operations in-house.

Pros

- Frees up time: When you’re not packing boxes and running to the post office, you have more time to focus on other aspects of your business.

- Lower shipping costs: Because they have multiple clients, most fulfillment services have discounted volume shipping rates they pass along to their customers.

- Fast delivery: Many fulfillment companies have warehouses strategically located across the country to ensure fast delivery and lower shipping rates.

- Flexibility: Using a fulfillment partner makes it easier to handle sales spikes or slowdowns in a cost-effective manner.

Cons

- Less control: When you outsource fulfillment, you are not directly overseeing the process.

- More expensive: Using an order fulfillment company can cost more than self-fulfilling.

3. Drop Shipping

Suppliers handle every step of the order fulfillment process, shiping orders directly to customers and billing the company for the products they sell. Drop shipping is a good option for startup ecommerce businesses or any online business that doesn’t want to purchase wholesale products upfront.

Pros

- No upfront inventory costs: When you drop ship products, you only pay for what customers purchase, so there are no bulk wholesale orders or leftover unsold products.

- No warehouse or storage fees: The drop ship supplier stores all products until they are sold, so you do not need a warehouse.

- Saves time: Similar to outsourced fulfillment, having someone else handle filling orders frees up time to focus on other parts of the business.

Cons

- Less control: You don’t see any part of the order before it reaches the customer.

- Smaller profit margins: Drop shipping can be more expensive than sourcing wholesale products in bulk.

4. Hybrid Order Fulfillment

This approach combines some, or all, of the above order fulfillment options. This is a popular solution for growing businesses because it offers a lot of flexibility. For example, you can use in-house fulfillment for custom products or items that need to be assembled. You can use outsourced fulfillment for non-custom items that are steady sellers or to help manage seasonal sales spikes without expanding your warehouse. Use drop shipping for large, expensive or infrequently purchased products that you do not want to stock in-house.

Pros

- Flexibility: Using different strategies for fulfillment allows you to add products or change directions easily.

- Strategic: A hybrid approach can often be cost-effective if you are strategic about which products are fulfilled with each solution.

Cons

- Lots of moving parts: Having inventory spread across multiple locations can be hard to manage.

- Time-consuming: Juggling orders across different solutions can also be time-consuming.

Issues Companies Experience With Order Fulfillment as They Grow

It’s often hard to anticipate your needs, and as your business grows, order fulfillment becomes more complex.

Operational

Ecommerce sellers don’t always know what their marketing plans will be and therefore, they don’t select an order fulfillment partner that can support custom needs. Most ecommerce companies only focus on getting help with picking and packing when they start out — and may not be thinking about marketing inserts, custom packing lists, or product bundling. However, what they need is flexibility and a fulfillment partner who supports these changes.

Strategic

You may assume your warehouse should be in the middle of the country, when in fact, it should be closest to your inventory and your customers. For example, is your product imported into California? Are most of your customers on the West Coast? If so, then it makes more sense to have a warehouse in California versus in the Midwest. Not only will you be able to receive inventory faster, you will be able to ship to customers faster and more affordably.

Most important when it comes to deciding on your order fulfillment process and partners, is setting your business up to scale. It can be difficult and expensive to switch fulfillment partners once you’ve started working with a vendor, so picking the right one at the start is crucial. In short, you need to anticipate your needs before you know you need them.

When to Switch From In-House Fulfillment to a Service Partner

Finally, how do you know when it’s time to partner with a fulfillment center? Here are the Top 5 Signs:

- Inventory costs are high while visibility remains low.

- Deliveries aren’t consistent and often arrive late.

- Customer complaints are on the rise.

- It’s hard to pinpoint the status of orders.

- Supply chain expenses are eating into margins.

How MasonHub’s Technology Supports and Scales Fulfillment

A modern fulfillment solution like MasonHub seamlessly combines order management technology and omnichannel fulfillment services. Moreover, by merging proprietary software with high-touch service, MasonHub checks all the boxes for retailers who prize efficiency, accuracy and innovation as much as the customer experience.

- Integrates quickly and easily with all your favorite ecommerce tools including Shopify, Netsuite, and Returnly.

- Handles volume spikes and scale over the long-term.

- Shows all your data in one centralized dashboard: details on every customer order; shipment statuses, carrier activity and delivery estimates; inventory data down to the SKU level with cross-channel visibility; status of pending and completed returns.

- Supports a true omnichannel strategy with real-time data from direct-to-consumer, retail and wholesale channels. Counts and dynamically allocates inventory across all channels.

- Offers dynamic shipping rate discounts.

- Allows customers to set customizable rules and guidelines.

- Goes above and beyond the average fulfillment offering.

– Branded packing slips

– Special packaging

– Gift messages

– Rush receiving

– Returns refurbishment